Healesville STP Sludge Tank

Tankweld was required to design, construct and install a new 225KL litre open-top steel tank consisting of multiple compartments.

Fulton Hogan

All Services

Water Utilities

Yarra Valley Water STP, Healesville, Victoria

Tankweld delivers piping, mechanical and structural design, specialist fabrication, onsite installation, project management and maintenance services.

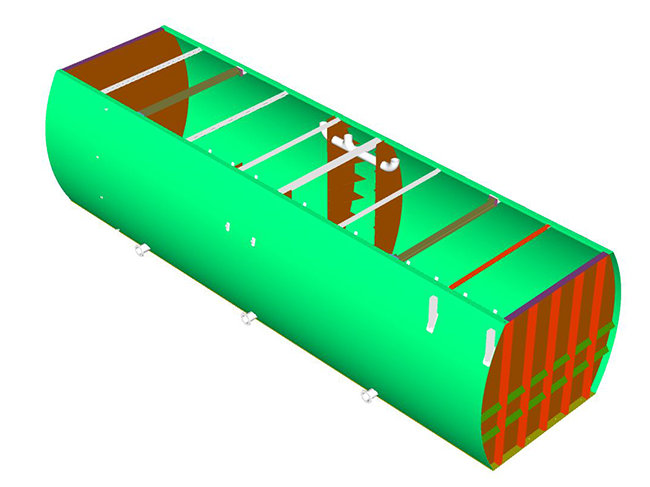

The Healesville Sewerage Treatment Plant is located approximately 65 km east of Melbourne and is owned and operated by Yarra Valley Water. Civil contractors Fulton Hogan was awarded the contract to upgrade the plant facilities. As part of this upgrade, Tankweld was required to design, construct and install a new 225KL litre open-top steel tank consisting of multiple compartments.

About the Project

The tank was of considerable size, 15m long, 4.7m wide and 4m high. Each compartment was required to be fully sealed and isolated from the others. In addition, the tank required a full-length walkway and access stairs, connection points and various bracketry for internal pipework and aeration system to be fitted later.

Tankweld engineers developed the initial design using 3D modelling. The tank’s features and design details were initiated and added during this design phase. Using computer modelling, Tankweld was able to adapt to the requirements with minimal scheduling impact quickly. Computer modelling also allowed us to identify areas of high stress in the tank structure and adjust the design accordingly.

Project Challenges

The isolation system between compartments also presented unique challenges. Not only did the baffle walls between the individual compartments have to be fully sealed and removable, but removal/installation of these baffles had to be performed from the central compartment only.

Using cranes to manoeuvre, transport and install the tank also had to be carefully planned following prevailing weather conditions. The sheer size of the tank meant that any lifting was considered a high-risk activity that could only be performed when wind gusts were less than 35km/h. Again due to its size, the tank required specialist road transport and associated travel restrictions on public roads.